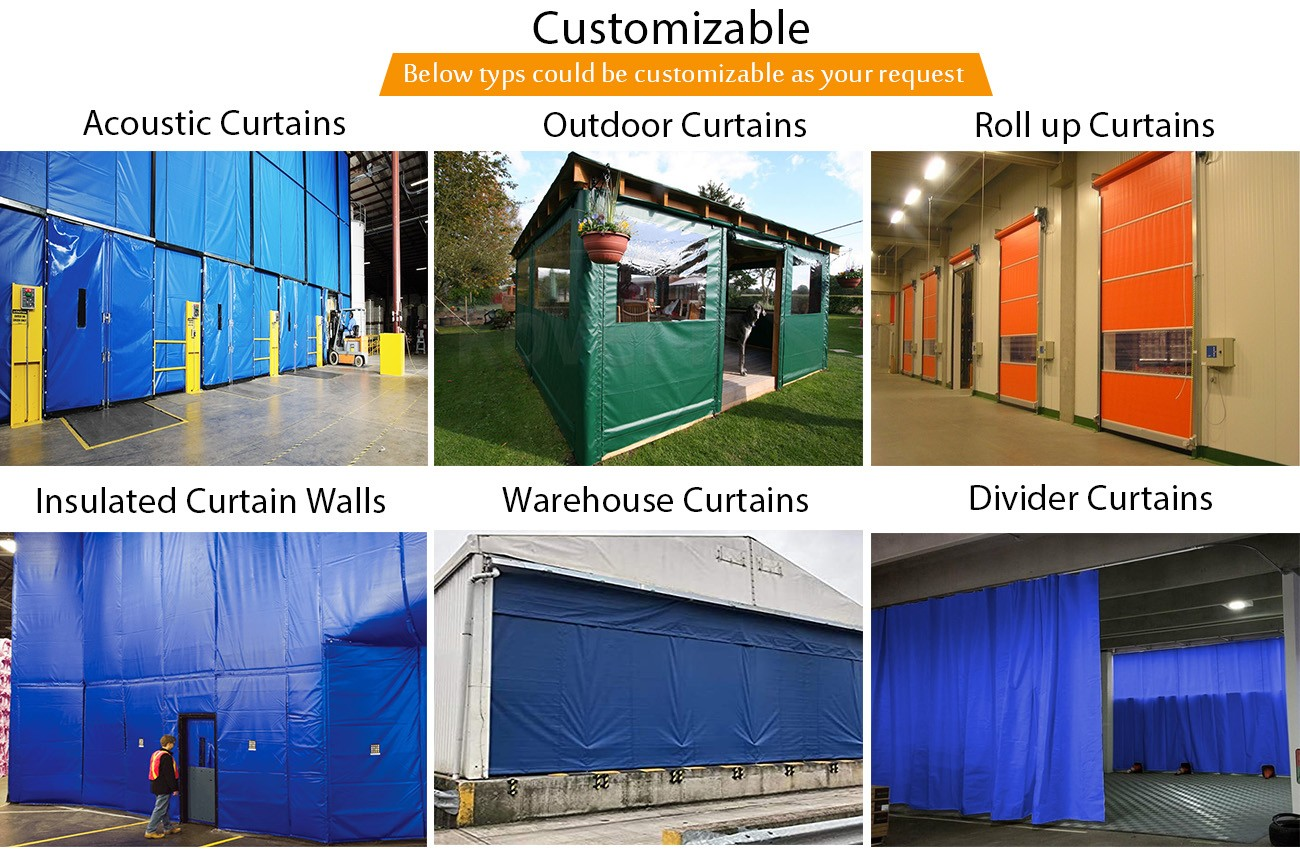

Our insulated partition curtains create a cost-effective way of separating temperature zones for many applications. Use them in freezer to freezer, cooler to cooler, freezer to environmental storage, food storage, and other work areas. They are easy to move and install. Because the cutain with Velcro, you can modify the size and adjust the size at will to allow large machinery or equipment to enter your temperature control area.

Benefits of insulated warehouse curtains:

●Easily create and quickly change the temperature of different areas in the freezer, cooler, warehouse, open dock or production area.

●Keep the temperature in each area consistent to maximize energy efficiency and reduce waste

●Create area space for temporary storage of refrigerated or frozen products

●Control the heat of production equipment or isolate the temperature control area

●Save the cost of building permanent rigid walls and take up less space

●No need to dismantle walls, reduce labor costs and waste of resources, and can be reused

Common Applications of insulated Curtains:

●Refrigerated & freezer areas

●Warehouse separation with temperature controlled space

●Loading dock areas

●Containment for storage and work space

●Food & beverage industry including food processing lines

●Third Party Logistics

●Data centers

●Airports

●Garage dividers/separation & insulation